Revolutionize your projects with premium sandblasted aluminum extrusions

What is sandblasted Aluminum Profile?

Sandblasted aluminum profiles undergo a special surface treatment: a high-pressure jet evenly applies abrasives such as aluminum oxide to the surface, creating a matte finish. This aluminum sandblasting process not only enhances the material's appearance but also its functionality. The resulting surface offers exceptional durability, effectively resisting corrosion, wear, and environmental stresses, making it ideal for both indoor and outdoor applications.

Advantages of Sandblasted Aluminum Surface Treatment

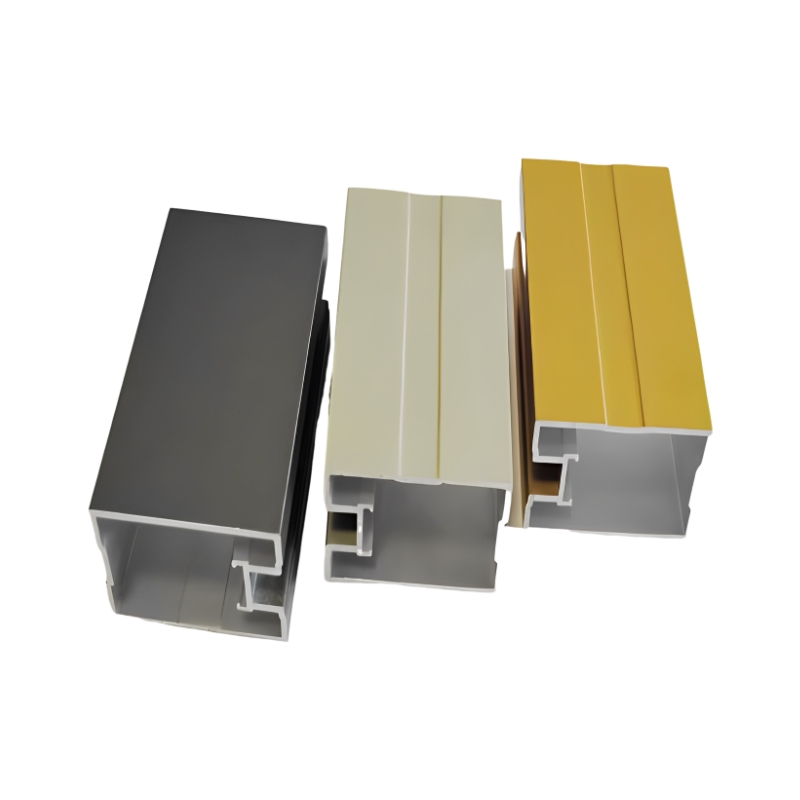

- Aesthetic Value: Sandblasted aluminum's refined, non-reflective surface complements modern architectural designs. Its delicate texture lends depth and elegance to structures, making it a favorite among designers and architects.

- Enhanced durability: Sandblasting aluminum components significantly improves paint adhesion by removing impurities and creating a micro-rough surface. This not only extends the material's lifespan but also effectively reduces maintenance costs for owners and developers.

- Environmental Sustainability:As industries transition towards sustainable practices, sandblasted Aluminum Extrusions represent an environmentally friendly option. Aluminum is fully recyclable, and the sandblasting process itself uses environmentally friendly media such as aluminum oxide – a safe, reliable, and reusable substance.

Cross-industry applications

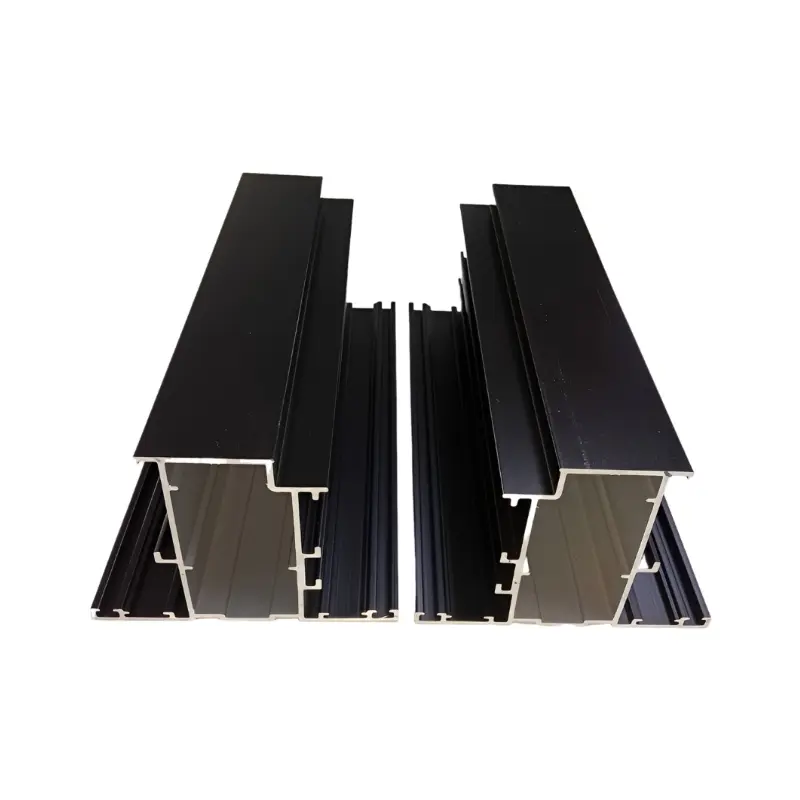

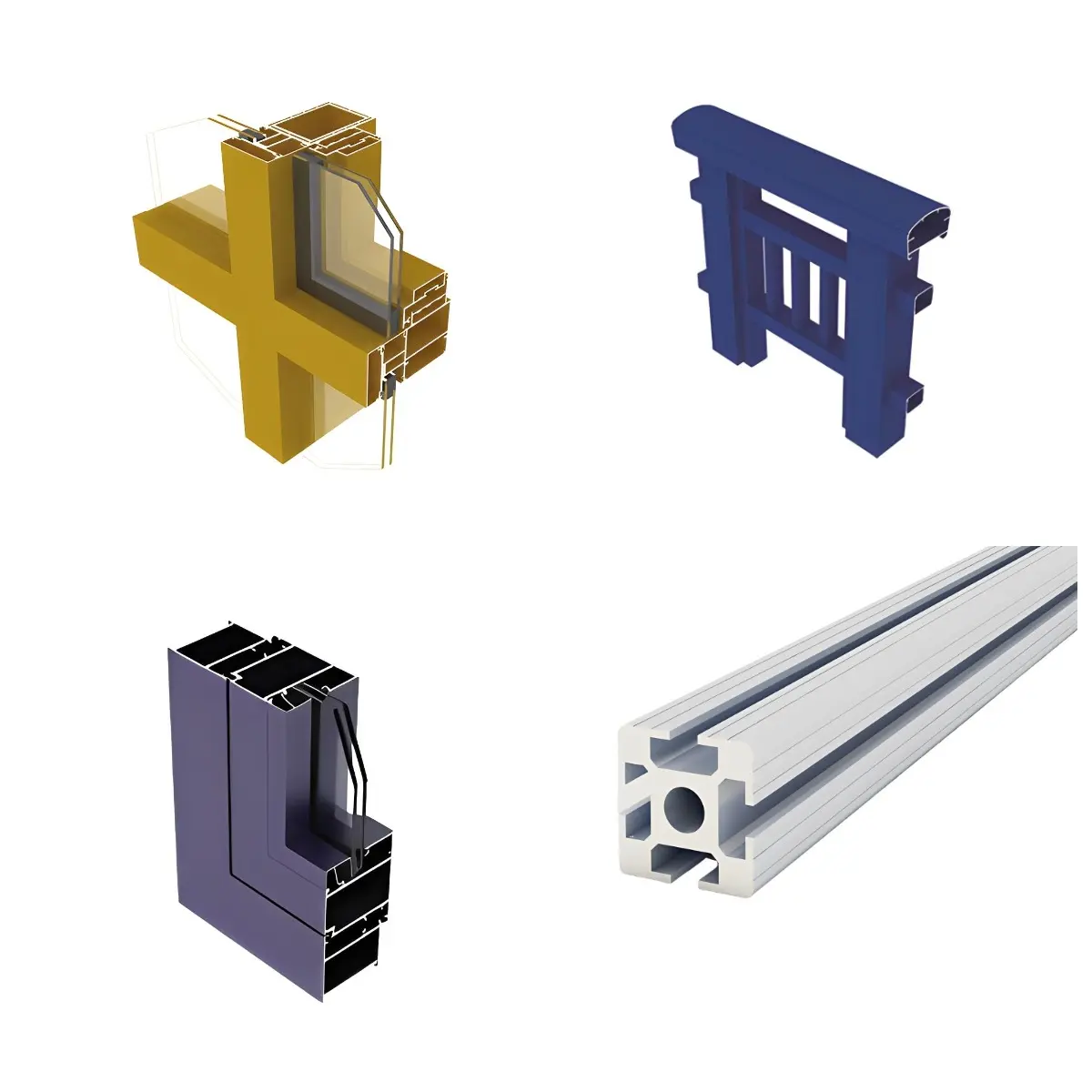

Architecture and Design: From streamlined window frames to sturdy curtain walls, sandblasted aluminum profiles combine strength and beauty. Their excellent corrosion resistance makes them an ideal choice for high-rise and coastal buildings.

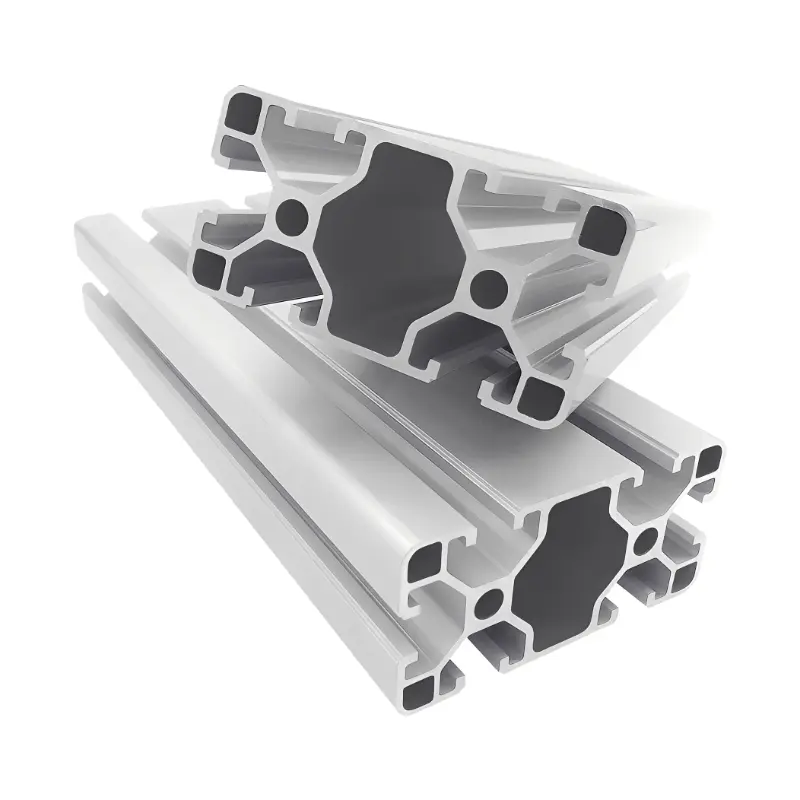

Industrial Manufacturing: In mechanical applications, sandblasting aluminum parts ensures a clean, contamination-free surface – essential for precision assembly.

Interior Design and Hospitality: Hotels and restaurants utilize sandblasted aluminum as decorative elements, furniture, and fixtures to create welcoming spaces through its aesthetic versatility.

Government and Infrastructure: Procurement officials prioritize materials that combine durability and cost-effectiveness. Sandblasted aluminum extrusions perfectly meet these criteria, making them particularly suitable for public projects like sustainable housing.

Is aluminum oxide safe as a blasting medium?

A frequently asked question about aluminum blasting: Is aluminum oxide safe? The answer is yes. Aluminum oxide is the preferred blasting medium for aluminum due to its high hardness, high recyclability, and low environmental impact. Compared to other materials, it produces minimal dust, ensuring workplace safety and reducing health risks.

During the profile blasting process, precise control of pressure and abrasive is crucial for achieving consistent results. Our state-of-the-art equipment utilizes automated systems to ensure that every blasted aluminum product meets international quality standards. This precise control is crucial for applications requiring tight tolerances, such as machining.

Why choose our sandblasted aluminum profiles?

Our sandblasted aluminum extrusions are produced using cutting-edge technology and exceed industry standards.

Customization: Custom sizes and finishes can be customized to meet project requirements.

Quality Assurance: Strict adherence to testing protocols for strength, corrosion resistance and surface uniformity.

Global Compliance: Production processes comply with international environmental and safety regulations.

Whether you’re a builder seeking a durable building material, a designer exploring new textures, or a government official searching for sustainable infrastructure solutions, sandblasted aluminum extrusions offer unparalleled advantages.

Visit our website to explore our full range of sandblasted aluminum products. Contact our team for a custom consultation and quote - let us bring your vision to life with our craftsmanship and innovation.