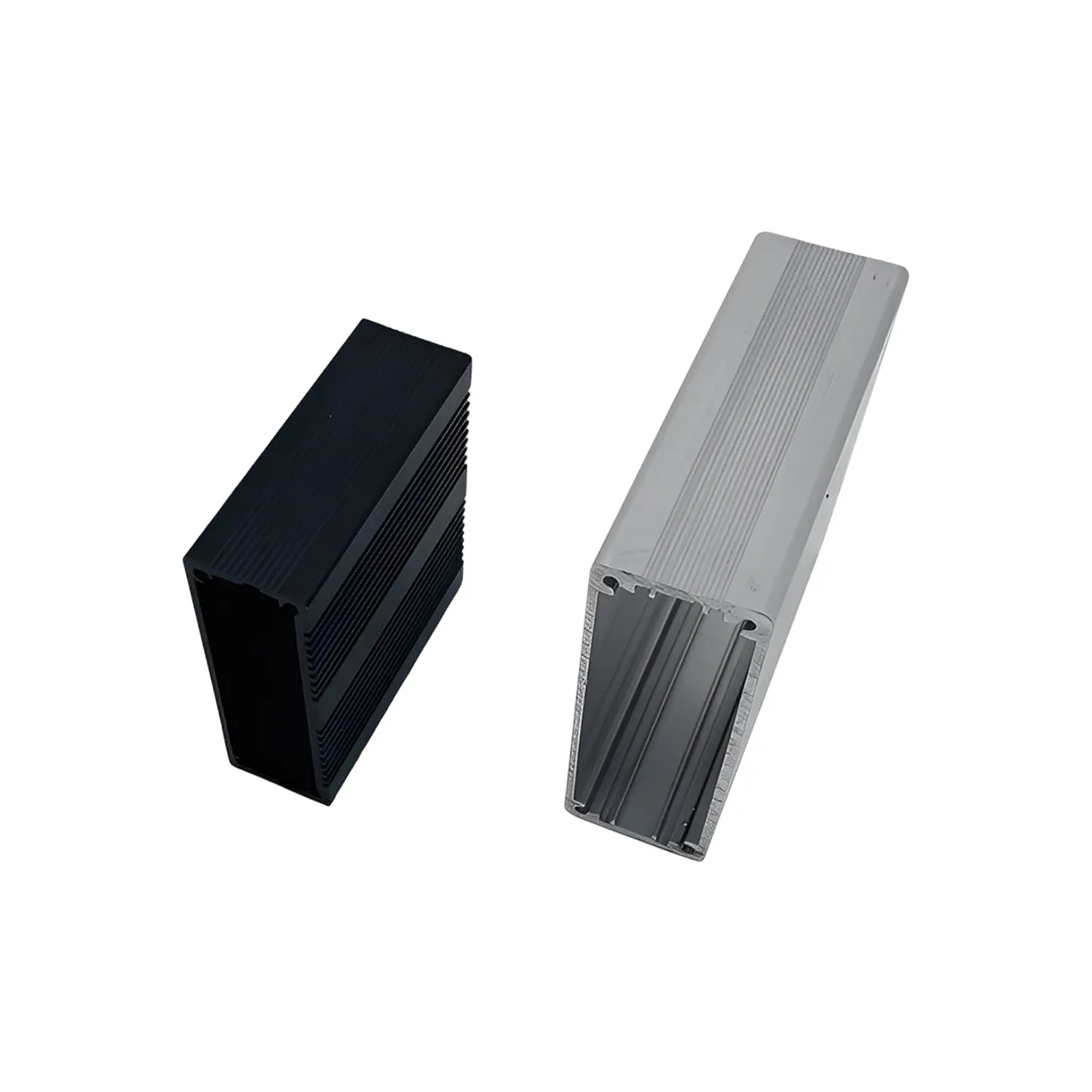

Aluminum Extruded Power Boxes: Electronic Equipment Protection and Heat Dissipation Solutions

Extruded Aluminum power boxes, with their lightweight yet high strength, are becoming an ideal choice for protecting electronic equipment in industries such as industry, communications, and new energy. In today's era of rapidly advancing electronic technology, power boxes, as core components for equipment protection, have a direct impact on the stability and service life of the entire system. With their excellent heat dissipation performance and rugged durability, extruded aluminum power boxes are becoming the preferred solution for industrial control, communications equipment, and power systems.

The core advantage of aluminum extruded power box enclosures lies in their excellent heat dissipation capabilities. The heat generated by electronic equipment during operation is the main factor affecting its performance and lifespan, and the high thermal conductivity of aluminum effectively solves this challenge.

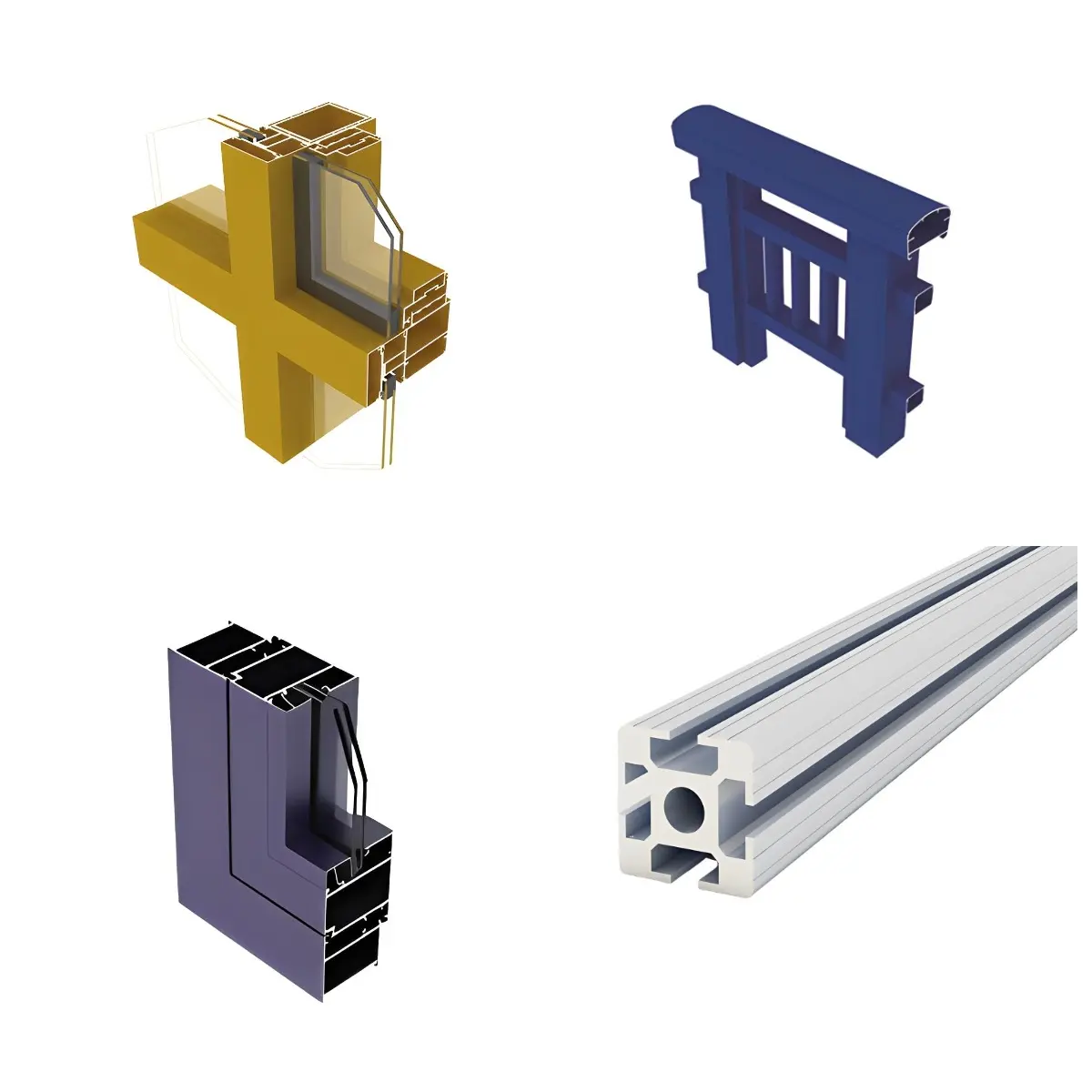

Compared to traditional metals, aluminum alloy has higher thermal conductivity, allowing it to quickly transfer internal heat to the surface for dissipation. Some high-end aluminum extruded power enclosures are equipped with heat sinks to further optimize heat dissipation. This inherent heat dissipation capability makes aluminum extruded power enclosures particularly suitable for high-power density applications such as LED power supplies and industrial control equipment.

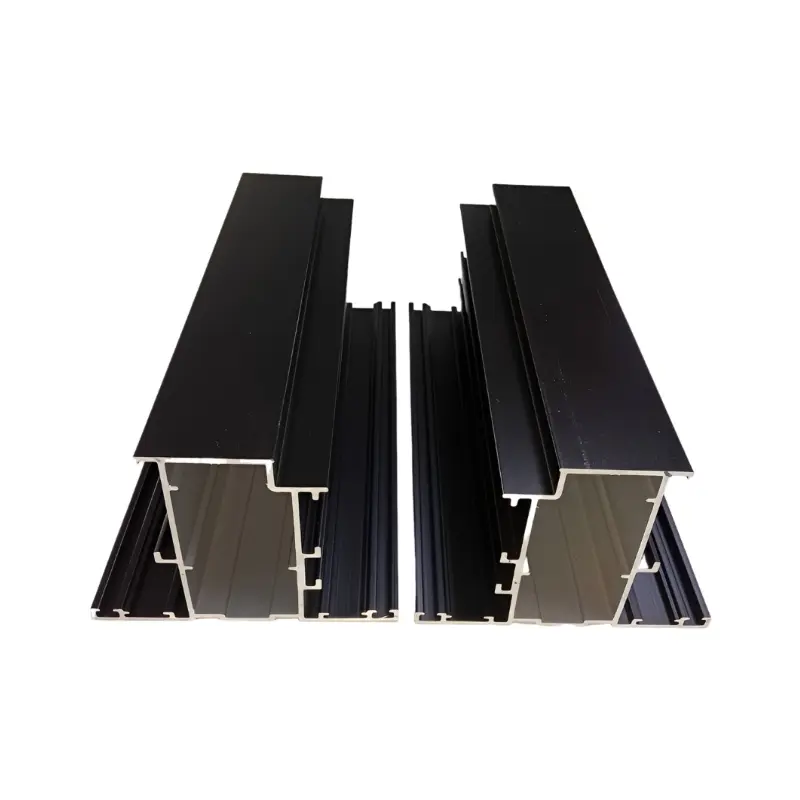

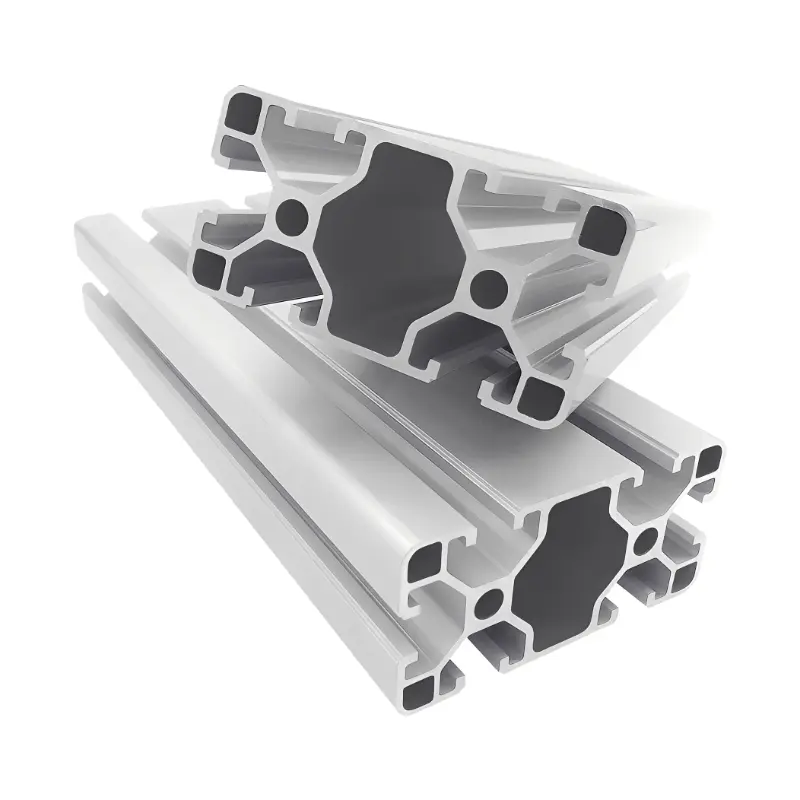

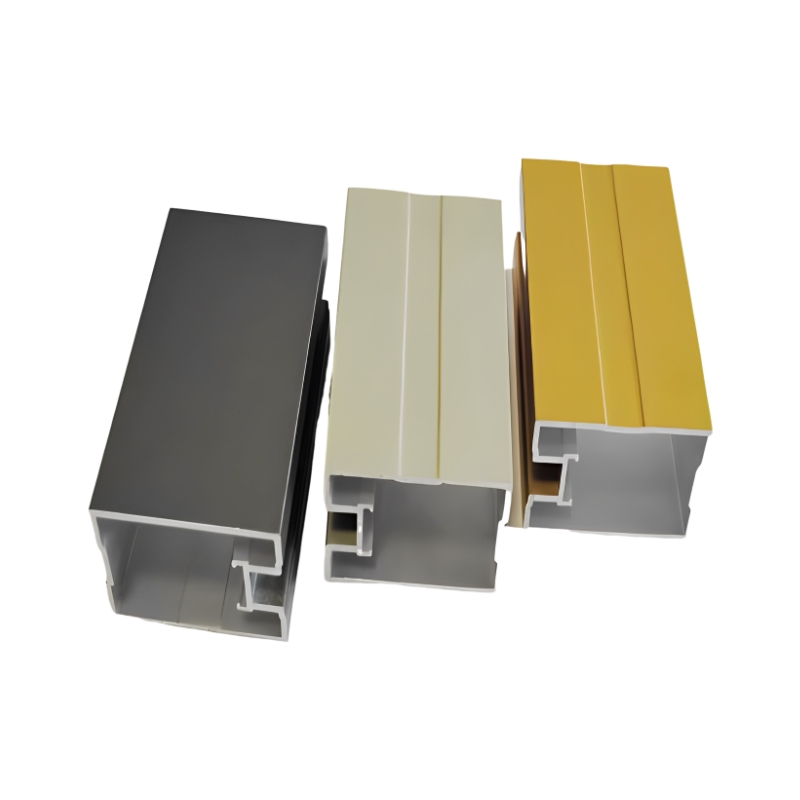

Aluminum power boxes are manufactured using an extrusion process that allows aluminum to be formed into complex cross-sectional shapes while maintaining structural integrity. This design flexibility allows manufacturers to customize the box structure to specific applications.

Common aluminum power boxes are made of aluminum-silicon alloys such as 6061, which are light in weight but have high mechanical strength.

The box frame is made of high-strength aluminum alloy, and the surface is sprayed or anodized to have corrosion resistance. These characteristics enable the aluminum power box shell to withstand strong vibration and impact in harsh environments.

Aluminum power supply enclosures are widely used across multiple industries. In industrial automation, they protect control boards, power modules, and terminal blocks. In the communications industry, they are often used in network equipment, servers, and base stations. For example, in mobile power plants and solar power plants, lightweight aluminum structures provide essential protection and heat dissipation.

With the increasing adoption of renewable energy and IoT devices, the demand for power enclosures with efficient heat dissipation and lightweight designs will continue to grow. Innovations in aluminum power enclosures will drive the development of more efficient and reliable solutions for protecting electronic devices. For customers seeking high-quality electronic equipment enclosures, investing in advanced aluminum extruded power enclosures means longer equipment life and lower maintenance costs—advantages that are crucial in the competitive modern industrial environment.

Need a custom Aluminum Extrusion box tomorrow? Send us your drawings; we'll extrude, cut, machine, and anodize to your order.