Custom industrial aluminum profiles | 39 years of aluminum expertise

Application

Your equipment frame, radiator or conveyor rail deserves better than a “close enough” extrusion. Our 39-year-old, 130,000 square meter facility specializes in custom industrial aluminum extrusions for engineers who don’t compromise on precision, speed and sustainability.

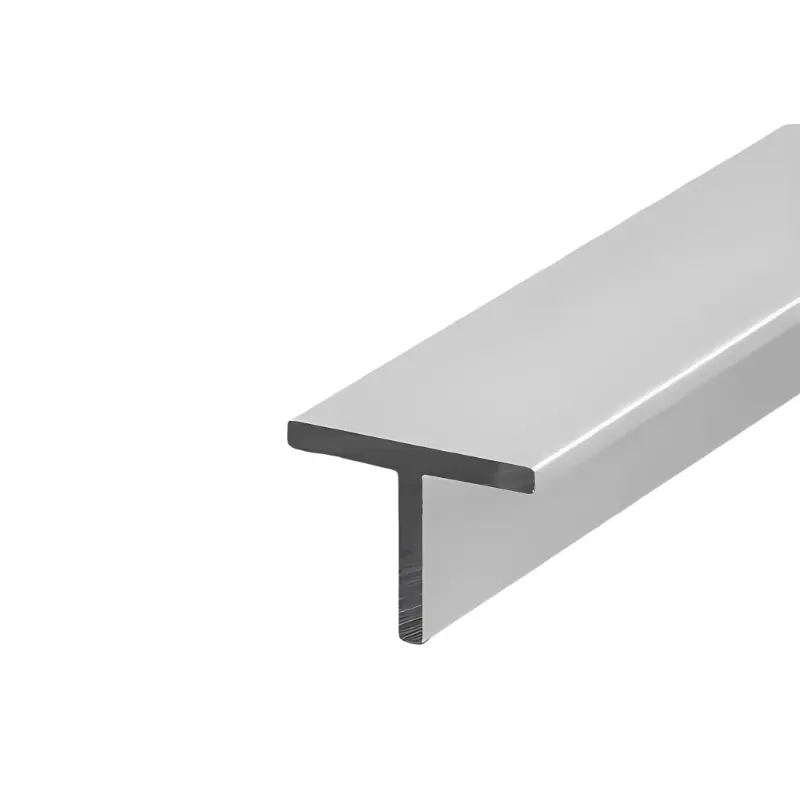

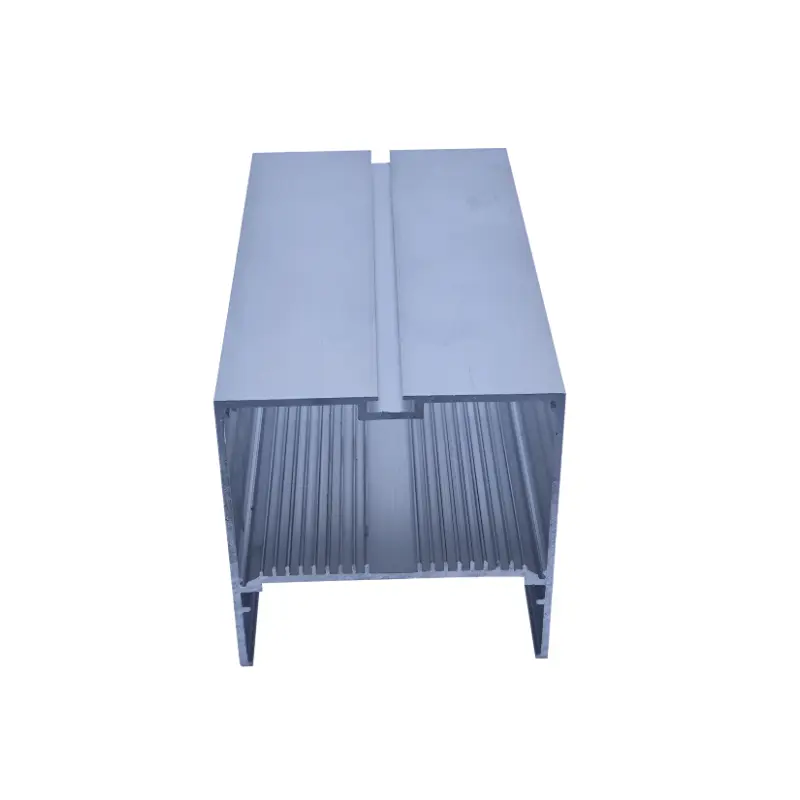

Accept any shape: T-slot, hollow, radiator, round tube, square tube, etc. Own mold workshop saves mold cost; new mold can be ready in 5-7 days.

14 extrusion lines (600-1400 tons) can process profiles with diameters from 1.0 mm to 3.0 mm and lengths from 6 to 12 meters. In-house casting ensures 100% purity and traceability of A00 grade aluminum ingots. The company provides CNC machining, drilling, bending and other services. Optional surface treatments such as glossy polishing, clear/black anodizing, powder coating, PVDF, brushing, sandblasting, wood grain, etc.

ISO 9001 and AAMA certified. During the manufacturing stage, quality inspectors conduct initial inspections on all types of profiles produced as soon as possible to confirm the profile size and surface quality to ensure that the profiles meet the requirements of standard machine customers. The standard delivery cycle for aluminum profile production is 7-20 days.

Industries Served: Automation Frames, Robotics, LED Lighting, Electric Vehicle Battery Pallets, Solar Mounts, Aerospace Equipment, Medical Equipment.

Upload your DWG or PDF file now - at a discounted price. Let us transform your blueprints into high performance aluminum.

| Brand Name | Luoxiang |

| Place of Origin | Foshan,China |

| Product name | Custom industrial aluminum profiles |

| Material | 6063 /6061/6000/6082 |

| Technology | extrusion |

| Finishes | Anodising, electrophoretic coating, powder coating, etc. |

| Color | Customized |

| Delivery Date | 7-20 days after receipt of payment |