Aluminum channels: versatile and durable

Application

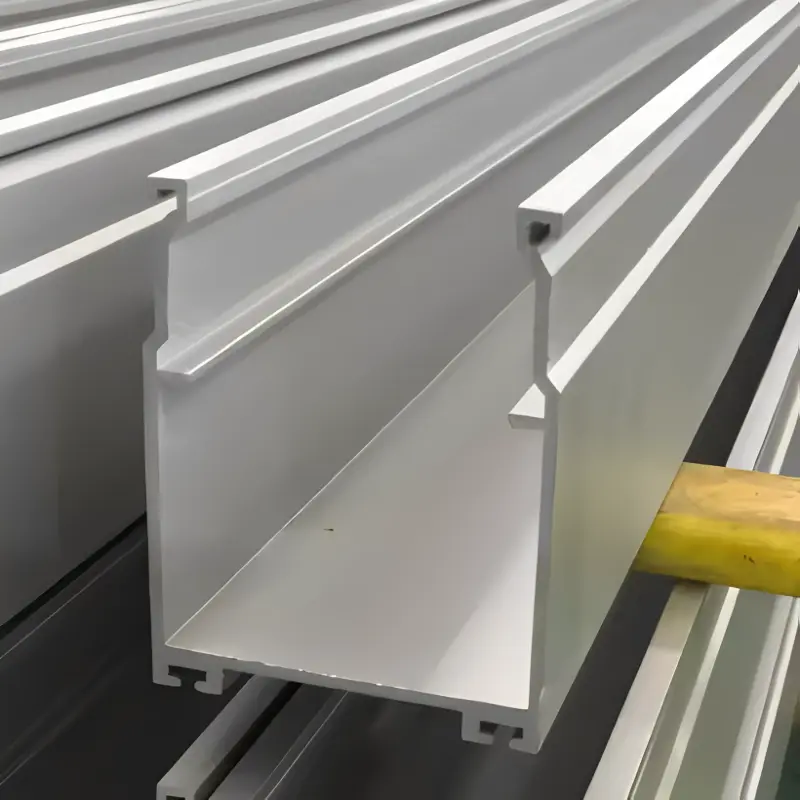

Our aluminum channels are made from 6063-T5 and 6061 alloys, known for their superior strength-to-weight ratio and corrosion resistance. Through a precision extrusion process, profiles maintain dimensional stability within ±1% even under heavy loads. Surface treatments such as anodizing or powder coating provide additional protection against UV, moisture and chemical corrosion, making them suitable for outdoor signs, automotive decorative parts and coastal installations.

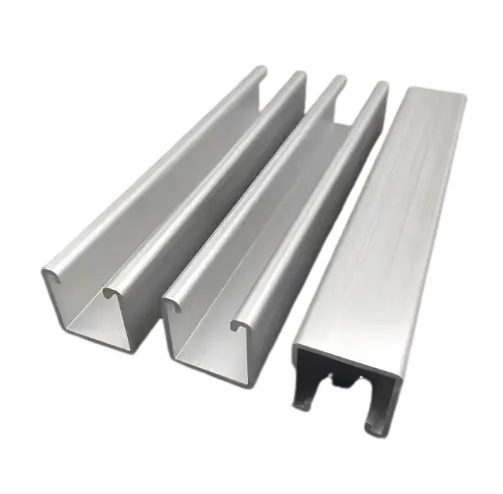

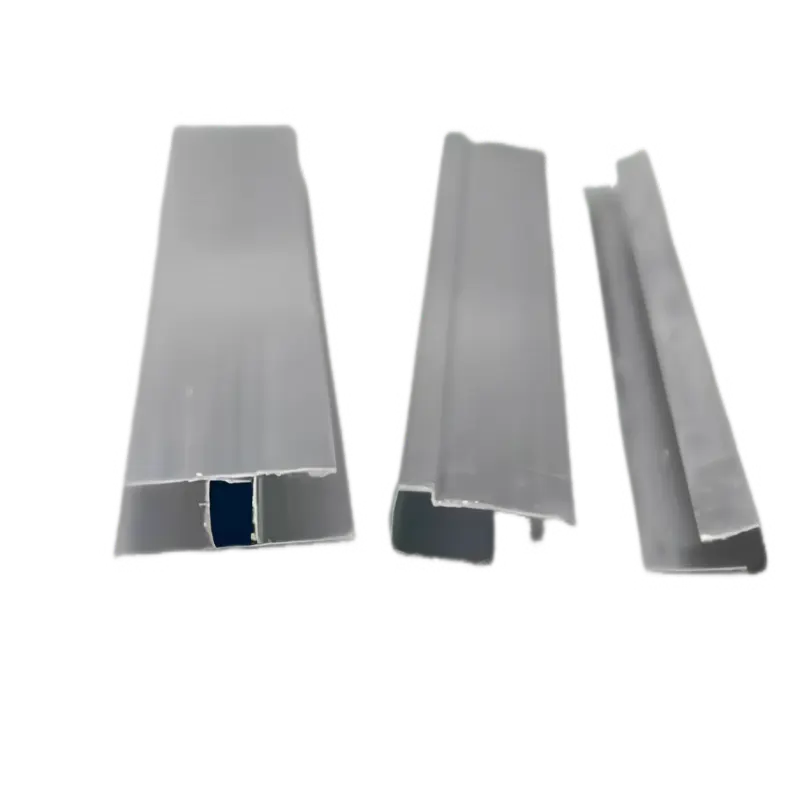

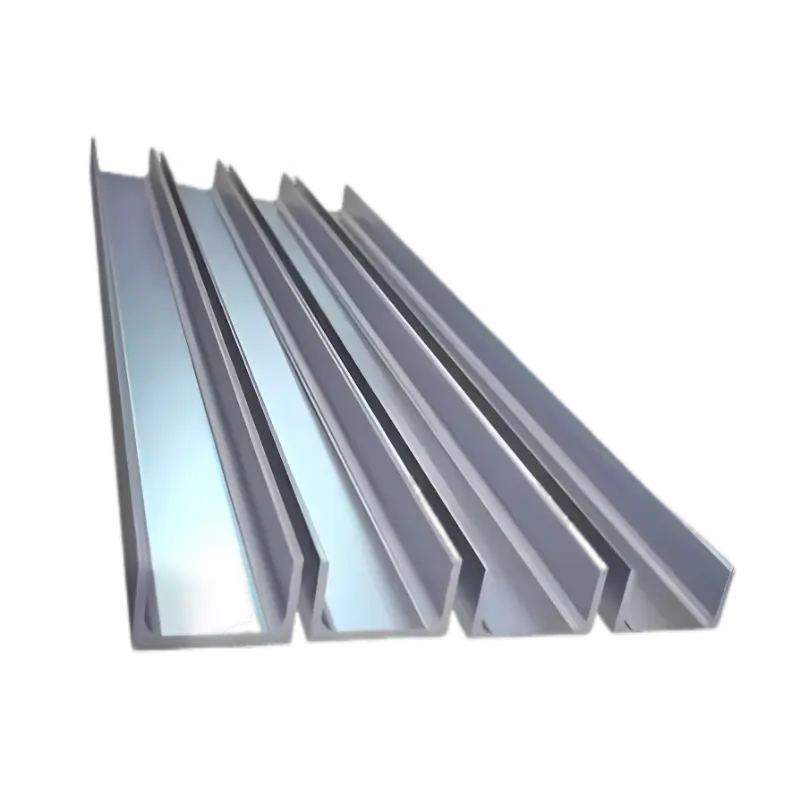

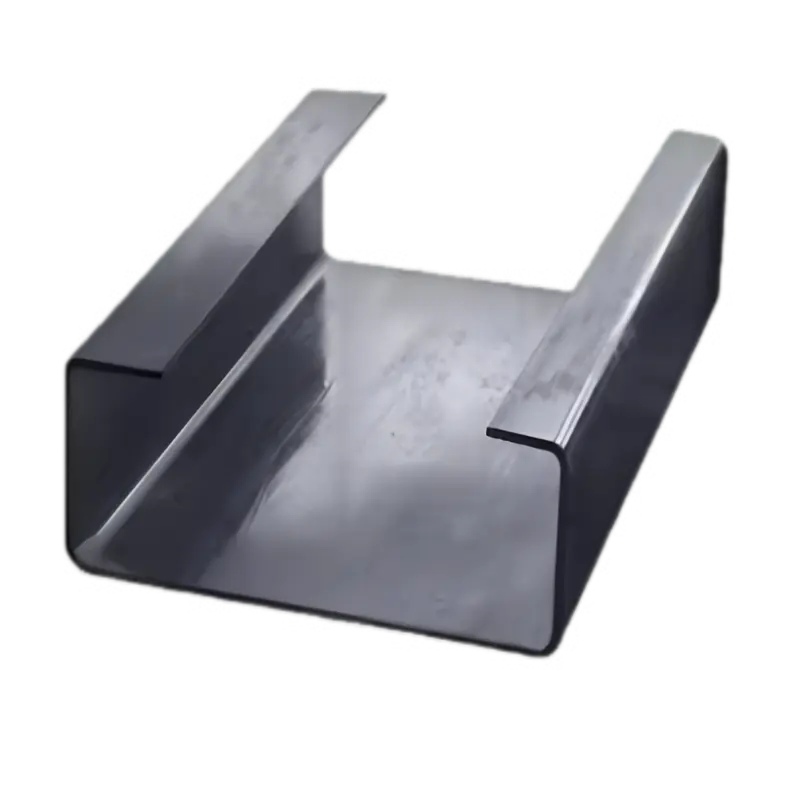

There are many types of aluminum channels, including U-, C-, J-, Z-, T- and H-channels. Each channel type has its own unique shape and characteristics, suitable for different applications. For example, U-channels are often used in construction projects to support doors, windows and glass panels; C-channels are suitable for mounting picture frames and lighting fixtures; J-channels are often used to install exterior wall panels and roofing materials; T-channels are widely used in the manufacturing industry.

Ideal for creating environments for mounting brackets, fixtures and workstations as they can easily secure components and accessories. They are corrosion resistant and suitable for harsh environments such as outdoor, marine and chemical processing.

We offer customization services based on specific needs. Customers can specify size, shape, material grade, surface treatment and other parameters to meet the unique needs of their project. This flexibility makes aluminum profiles an ideal solution for a variety of complex and demanding applications.

Excellent processing properties make it easy to cut, weld, bend and machine. This makes on-site processing and installation faster and more convenient, saving time and labor costs. In addition, its simple installation method, such as using bolts and nuts or special connection accessories, also makes the installation process more efficient.

To enhance appearance and durability, aluminum channels can be treated with a variety of surface treatments, including natural finish, mechanical sandblasting, grinding, polishing, brightening, color coating, anodizing and powder coating. These treatments not only enhance the corrosion and wear resistance of aluminum extrusions, but also provide customers with a wealth of aesthetic choices.

Enhance your projects with industrial-grade precision—request a custom quote or a free sample kit today!

| Brand Name | Luoxiang |

| Place of Origin | Foshan,China |

| Product name | Aluminum channel |

| Material | 6063 /6061 |

| Technology | extrusion |

| Finishes | Anodising, electrophoretic coating, powder coating, etc. |

| Color | Customized |

| Delivery Date | 7-20 days after receipt of payment |