6000 Series Aluminum Extruded Profiles

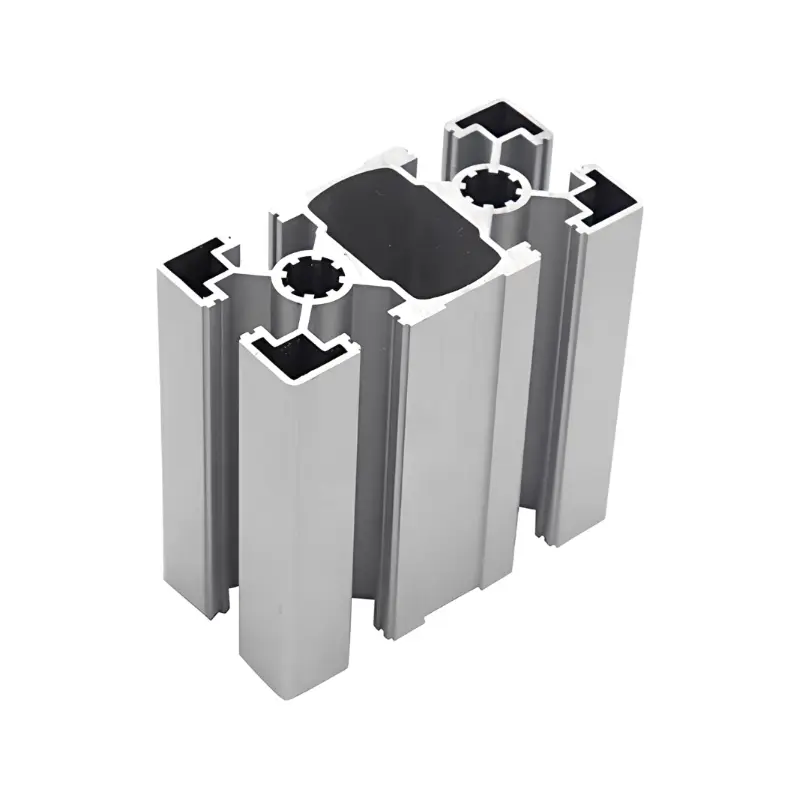

When your project demands performance exceeding that of standard profiles, our 6000 Series aluminum extrusion profiles become your reliable structural pillars. These alloys are made from premium aluminum with controlled additions of magnesium and silicon precipitates. The T5/T6 tempering process further enhances their tensile strength. Frames, supports, conveyor belt rails, and building components constructed from this alloy can withstand heavy loads without adding weight to production lines, vehicles, or buildings.

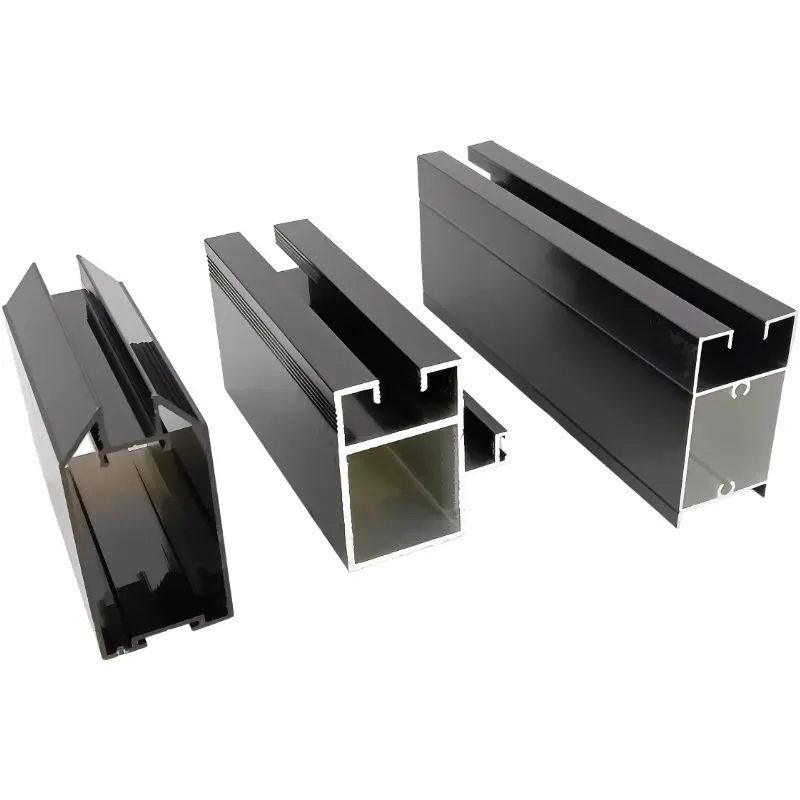

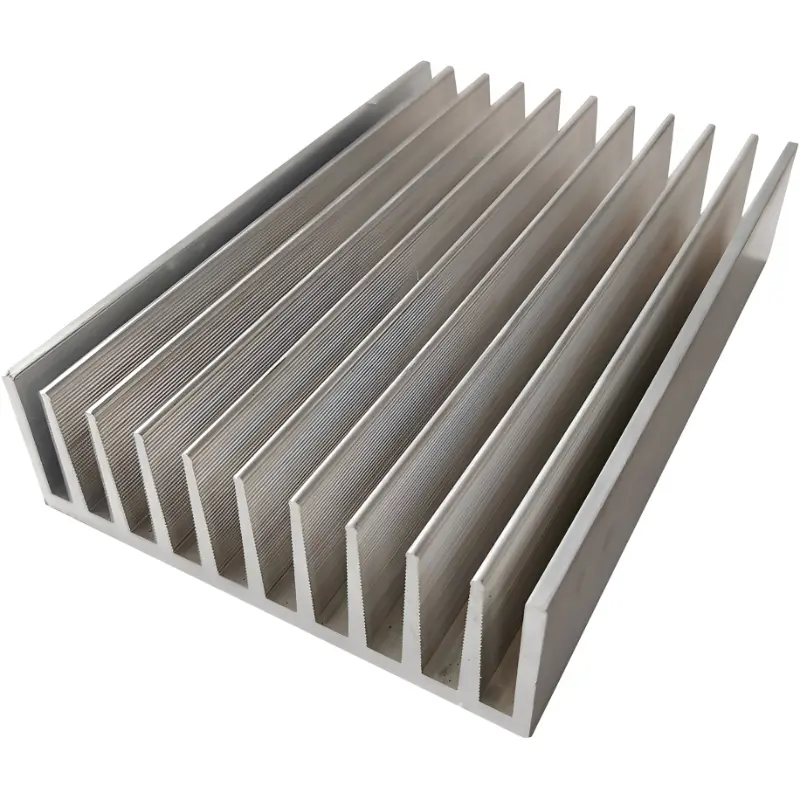

6063 extruded aluminum boasts unparalleled surface finish, making it ideal for decorative applications such as furniture frames, LED light troughs, and display cases. Need even higher performance? 6061 and 6082 aluminum alloys offer greater strength while maintaining a silky-smooth surface, making them ideal for robotic workstations and solar panel structures. Each profile is pressed using a 600-1800 ton press, resulting in a naturally smooth surface suitable for anodizing, powder coating, wood grain transfer, and even electropolishing mirror finishes. You can choose the raw material surface for rapid prototyping or opt for a 15-micron anodized layer for 1000 hours of salt spray resistance.

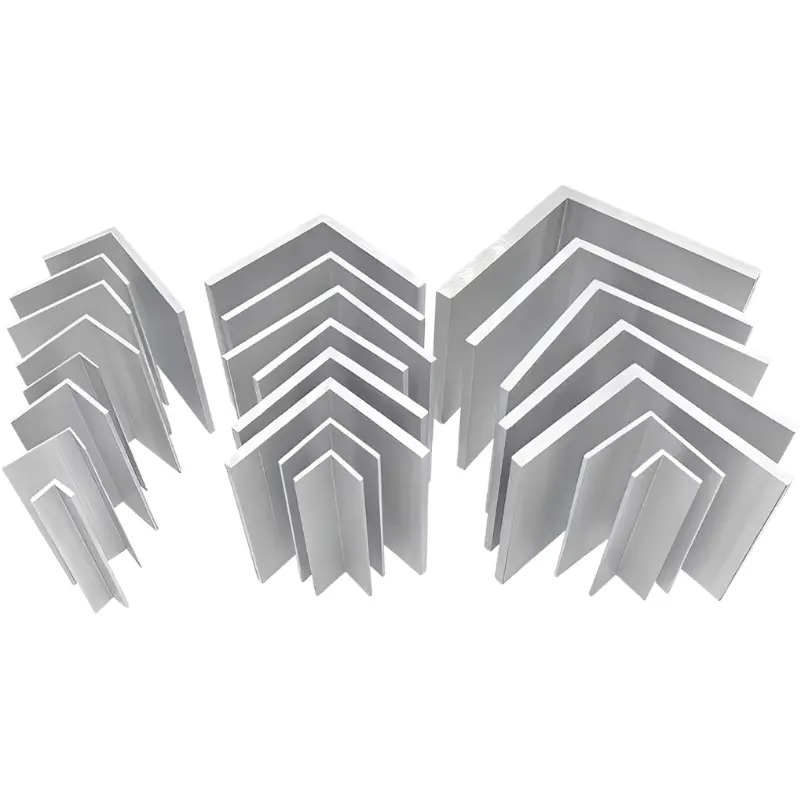

We possess a dedicated mold library containing thousands of standard molds, covering square, rectangular, T-slot, L-slot, Z-slot, H-slot, tubular, channel, and finned profiles, and welcome custom drawings from customers. Our engineers utilize software to optimize wall thickness, radius, and reinforcing ribs, reducing weight without sacrificing rigidity. After extrusion, the profiles can be cut to an accuracy of ±0.1 mm and can be machined by CNC milling, punching, chamfering, or tapping. The profiles are packaged in EP paper and shrink film and shipped from Foshan, Guangzhou, or Shenzhen. The 6000 series aluminum extruded profiles offer excellent weldability, corrosion resistance, and aesthetics, making them a reliable solution for modern industry.